Riveting Countersunk rivet can realize easy joint from one direction

Welding Sample conditions of gas protected welding: Welding temperature: 230-240℃ Pressure of air compressor:0.3-0.4kg/cm²

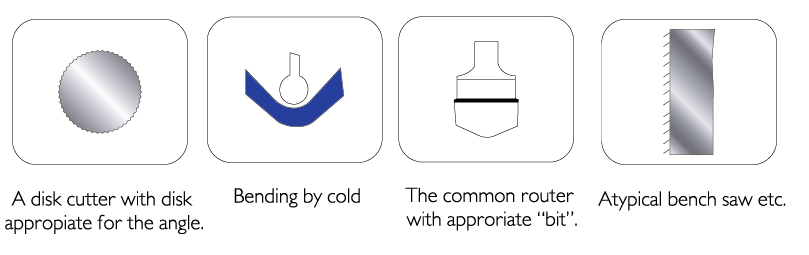

Cutting It can be easily processed with a wood product processing saw

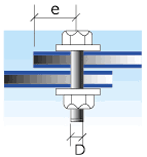

Bolting Considering from deformation limit form E ≥ 2D is the best Calculation way of aperture D and distance(E) from hole center to plate end.

Bending ALUSONG can be formed three dimensionally by means of conventional metal and plastic fabrication methods. The minimum bending radius is fifteen times the plate thickness.

Shearing ALUSONG can be easily sheared with a guillotine for thin sheets. A slight compression of the aluminium cover sheet on the edges may occur on the impact side. The clamp on the shear should be fitted with a shock-absorbing rubber pad to prevent damage to the cover sheet.

Glueing Excellent adhesion can be achieved even when using special adhesives

1. It is recommended to use the four-folding method.

2. If it do not need to fold, then it can be fixed by aluminum profile, and it can also be sealed with weatherproof sealant.

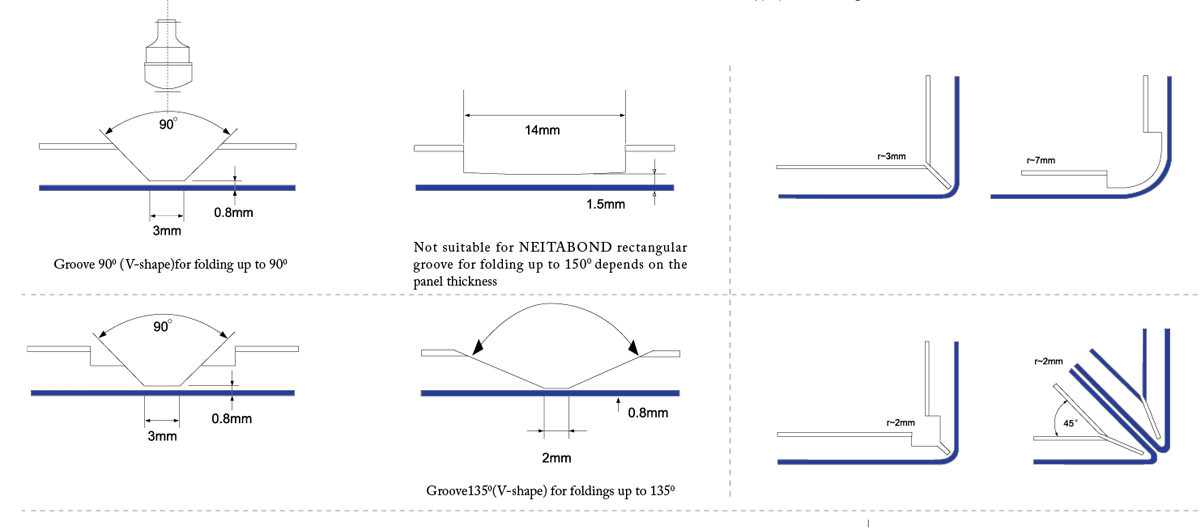

3. In the construction of folding, the groove should be grooved at the edge of hemming.Usually we can use V-grooves, U-shaped grooves, etc. Several typical groove patterns are shown in the figure.

4. While you use the aluminum composite panel grooving machinery, to ensure that the slot depth does not hurt the opposite aluminum, and we have to leave a 0.8mm thick plastic layer. In the slot can be used according to the need to strengthen the side ribs and other measures. Due to the different thicknesses and materials of the panels, this standard is for reference only. The specific standards for workers' slotting technology shall prevail.

1. Folding ALUSONG panel on a flat and steady work table. If we fold the panel with warping,, the folded line will not be straight.

2. The folded comer should have a suitable roundness of 2-3mm in radius. If the roundness is too small, the coating may have a crack on the folded corner. This tendency becomes apparent when we carry out the folding work at low temperature. Have a folding work at 10℃ or higher.

3. Folding after U-grooving entails slight elongation. The elongation is 0.5-1.0mm depending on the roundness of the folding corner. Therefore, the position of grooving lines must be prepared when the fabrication drawings are prepared.

Notes on folding:

Notes on folding: