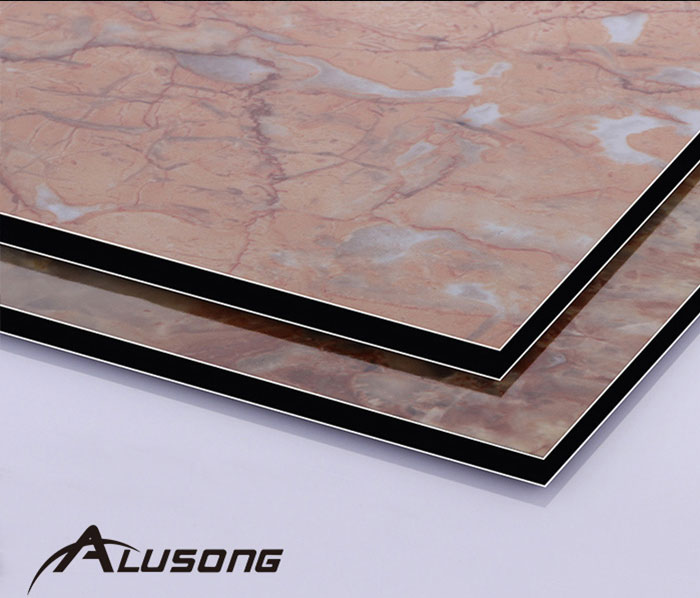

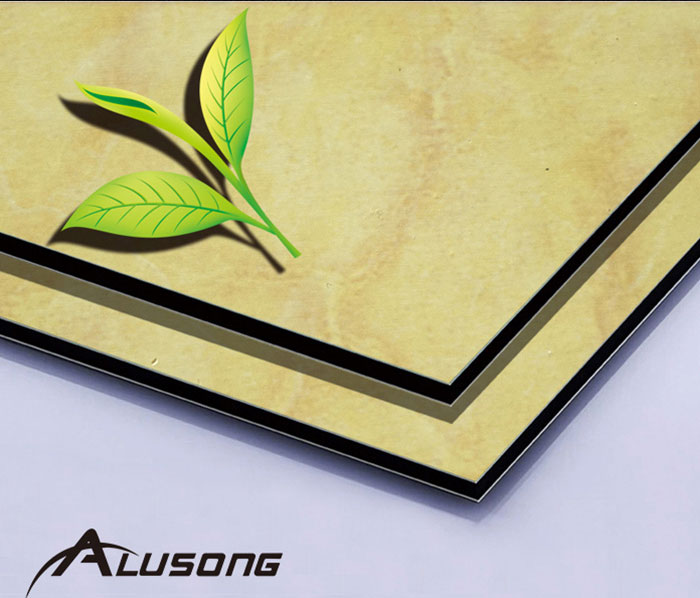

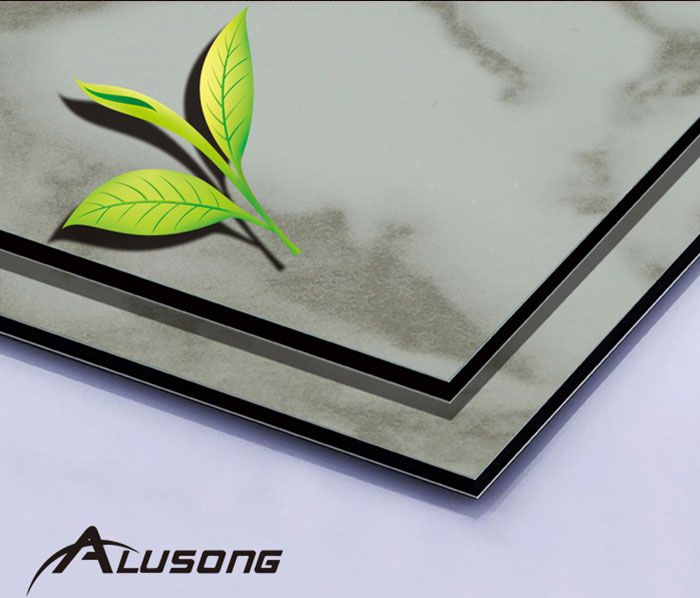

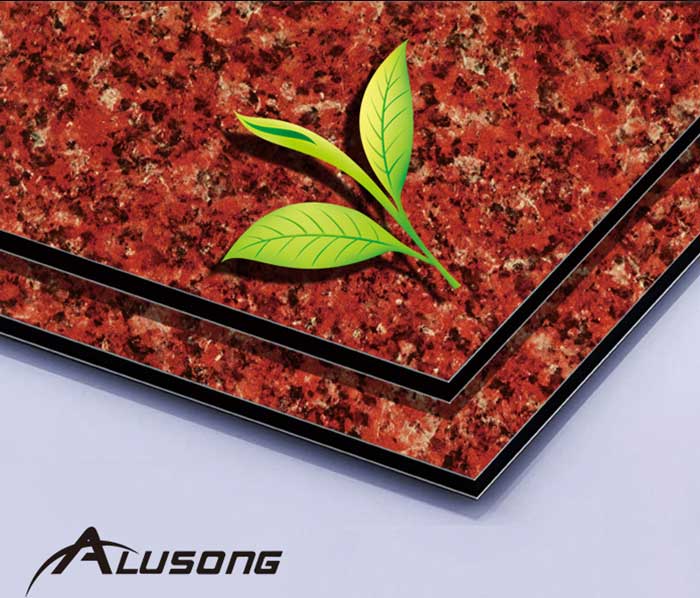

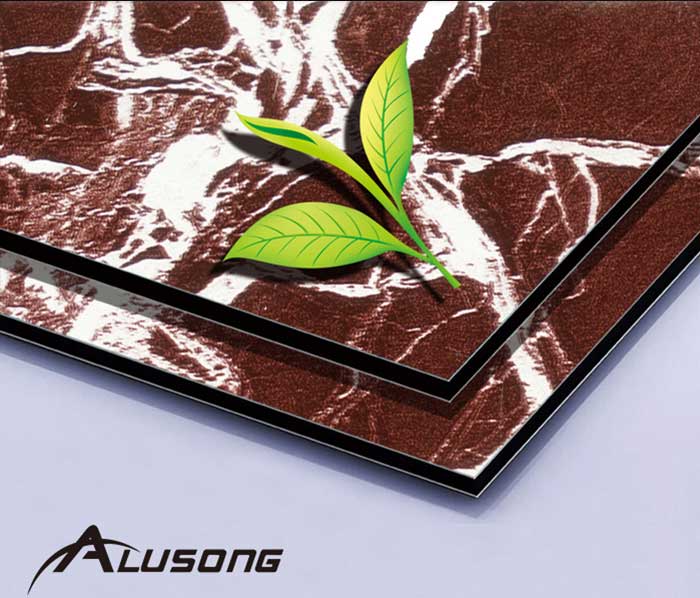

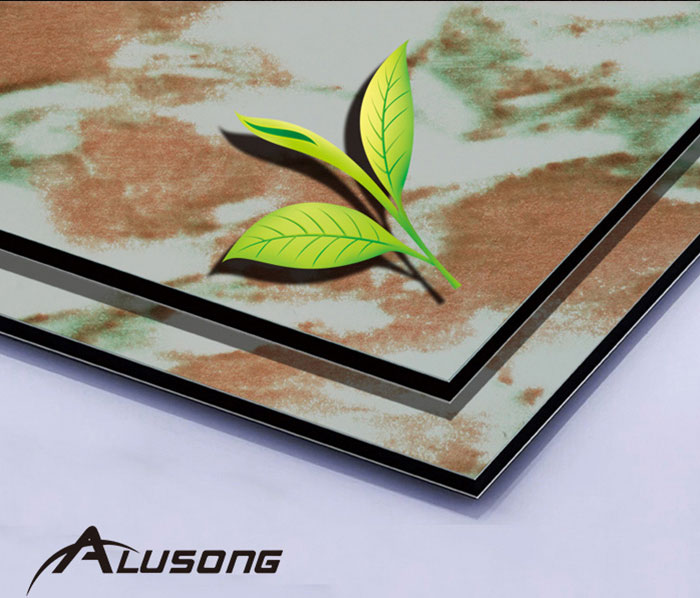

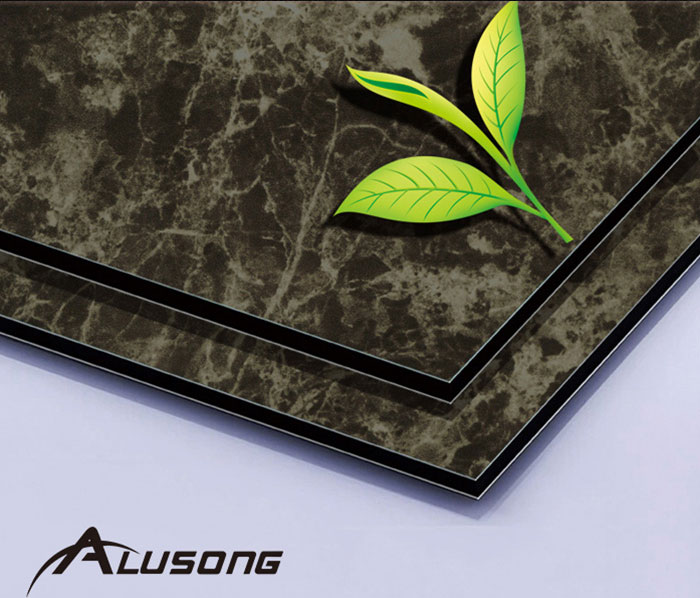

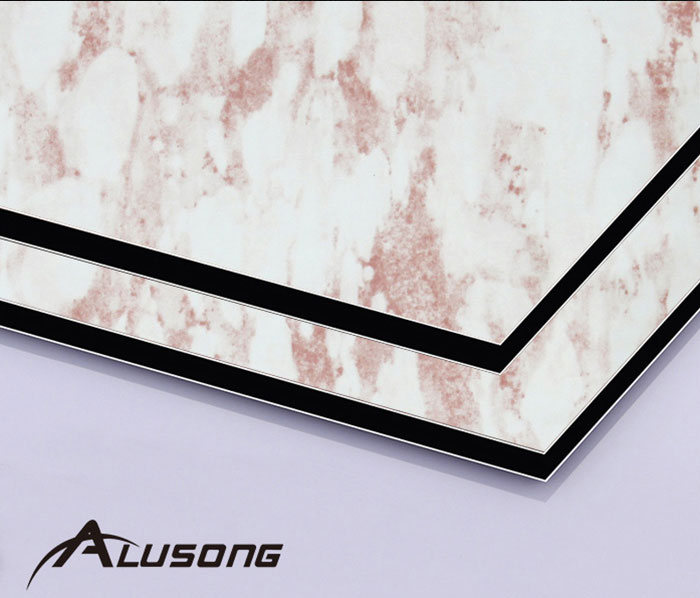

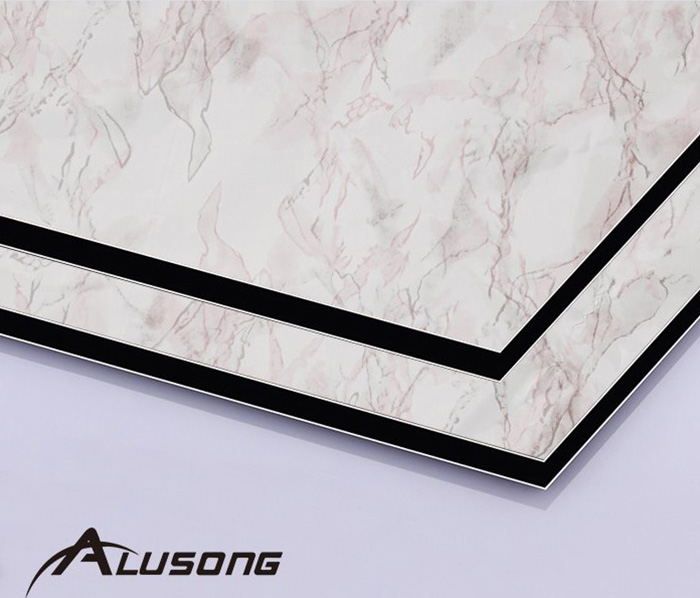

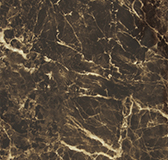

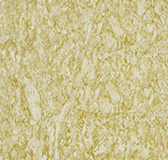

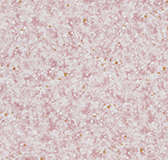

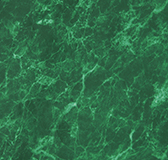

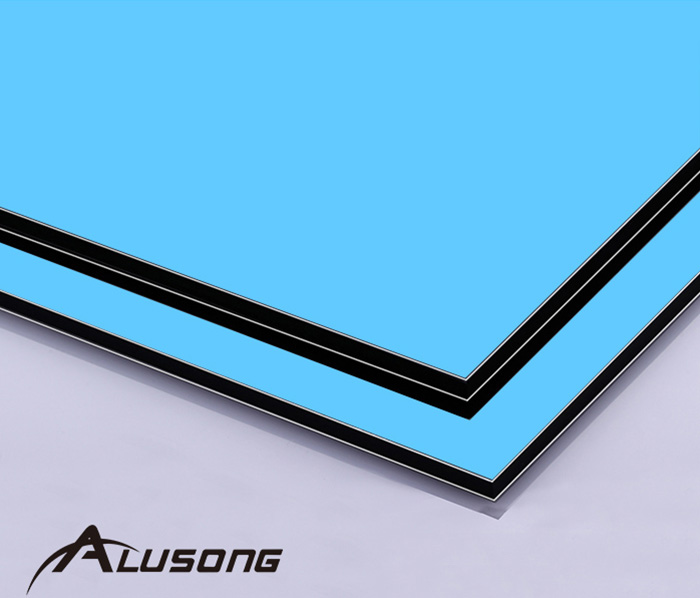

Marble grain aluminum composite panel is coated with PE(polyester) coatings or PVDF(fluorocarbon) coatings and comes with a great variety of marble grains for customer to choose from.

| Surface coating | PVDF marble coating | Polyester marble coating |

| Aluminum alloy | AA1100 series | AA1100 series |

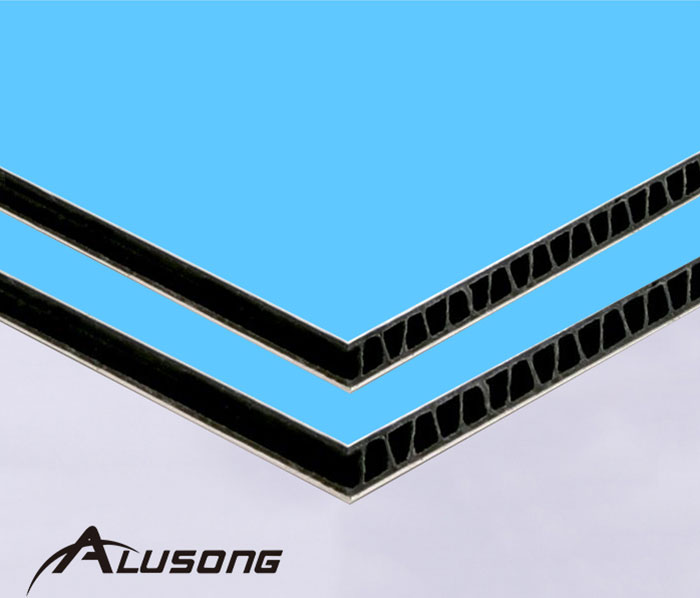

| Aluminum skin | 0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm | 0.08mm,0.10mm,0.12mm, 0.15mm,0.21mm,0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm |

| Panel thickness | 3mm ,4mm,5mm,6mm | 3mm, 4mm,5mm,6mm |

| Panel width | 1220mm 1250mm 1500mm | 1220mm,1250mm,1500mm |

| Panel length | 2440mm,3050mm,5000mm | 2440mm,3050mm,5000mm |

| Backing coating | Primer coating | Primer coating |

| Glossy | 20%-40% | 40%-70% |

Dimensional tolerance:

Panel width: ±2mm Panel length:±3mm Panel thickness:±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

Economy

High resistance to peeling

Superior weather resistance

Light weight and easy to process

Excellent fire resistance properties

Coating evenness

Diversified colors

Easy for maintenance

1. Wall curtain, Cladding and Facade

2. Interior decoration and furniture

3. Exterior renovation for old buildings

4. Subway and airports

5. Industry plants and materials,

6. Vehicle and boat materials

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint ≥16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | △E ≤ 2.0(follow color sample) | ΔE ≤ 2.0 |

| Pencil hardness | ≥HB | ≥2H |

| Chemical resistance | 2%HCI or 2% NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≥ 1grade for 10810mm2gridding test | 1grade |

| Resist solvent | 100times with Dimethylebnzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≥5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average drop rate≤10% | Change of glossy only, no paint Peel off |

| Coefficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition,glossiness deviation less grade 2, color difference ≤4.0 | No change |