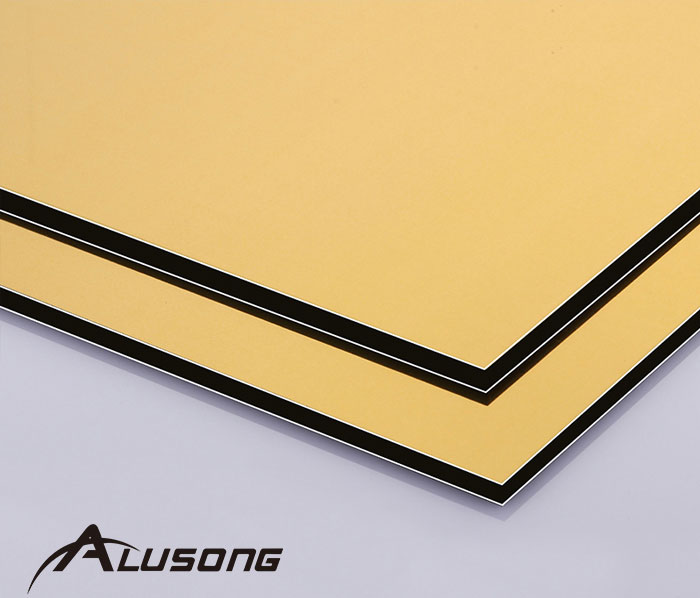

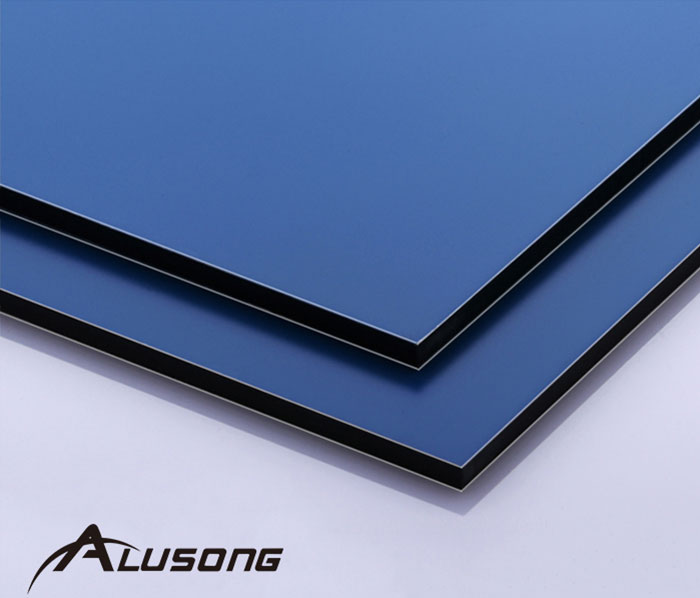

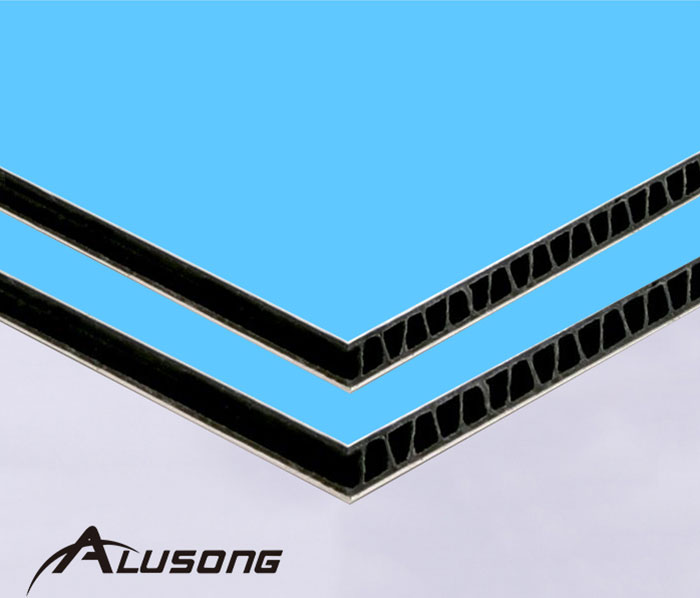

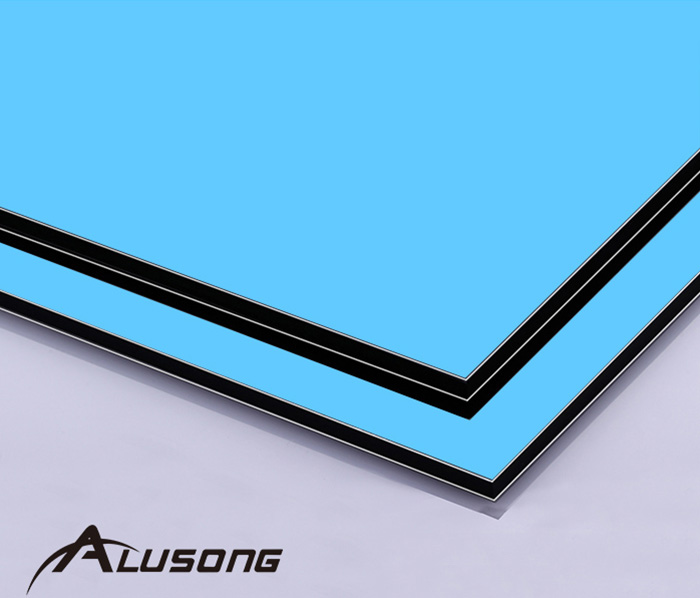

ALUSONG Eco is a dual-sided product with a high gloss finish on one side - the same PE paint finish as used on the premium ALUSONG sheet and a matte finish on the reverse. Specifically designed for applications where a high load-bearing capacity is not required, ALUSONG Eco offers a reduced weight, economical option for a variety of applications. ALUSONG ECO Aluminium composite panels are a highly efficient, economic solution for all flat applications.

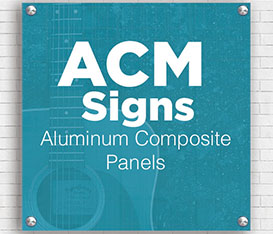

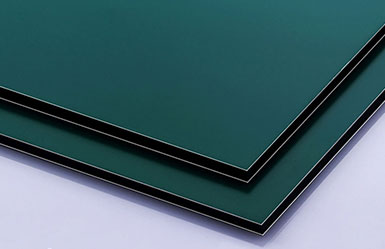

NEITABOND Signage grade aluminum composite panel is coated with a high-performance polyester lacquer which is weather resistance .It is very suitable for screen -printing flat digital printing ,the application of adhesive film, and post-painting using the liquid spray technique.

| Aluminum alloy | AA1100 series |

| Aluminum skin | 0.15mm,0.18mm,0.21mm |

| Panel thickness | 2mm,3mm,4mm |

| Panel width | 1220mm,1250mm,1500mm |

| Panel length | 2440mm,3050mm,4050mm |

| Surface treatment | UV digit printing ,Polyester coating |

| Glossy | 20%-80% |

Dimensional tolerance:

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

UV resistant for exterior use

High resistance to peeling

Superior weather resistance

Light weight and easy to process

Flat,smooth,uniform surface

Easy-peel film

Compatible with vinyl lamination

Easy for maintenance

· Sign Making, Way finding

· Direct UV & Screen Printing

· Standoff Lettering

· Lightweight Hanging Signs

· Displays &Vinyl Application

· Modular Sign Systems

· Hoarding Panels

· Exhibition Design

· Outdoor Advertising

-

Application

-

Application

-

Application

-

Application

-

Application

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint >=16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | ΔE≦2.0(follow color sample) | ΔE≦2.0 |

| Pencil hardness | ≧HB | ≧2H |

| Chemical resistance | 2%HCI or 2%NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≧1grade for 10810mm2gridding test | 1grade |

| Resist solvent | 100times with Dimethylebnzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≧5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropprate≦10% | Change of glossy only,no paint Peel off |

| Cofficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition,glossiness deviation less grade 2,color difference ≦4.0 | No change |