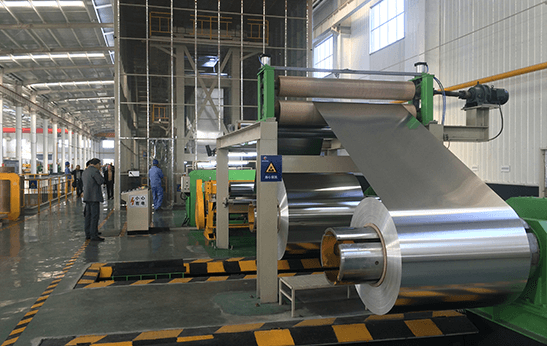

ALUSONG has two aluminum coil degreasing lines. The chemosynthesis lines is to clean the lubricating grease and anti-oxidative grease adhesive to the surface while being rolling, and other impurities such assilicon, magnesium, iron and copper that deposit on the surface of aluminum materials, we use qualified industrial and advanced technology from Germany Henkel to have a chemosynthesis dealing with the surface of aluminum materials, through this technology, the aluminum surface is covered with a honeycomb oxidative coating of high density, which becomes an agent to make paint and aluminum firmly adhesive with each other. This agent has very strong adhesive force. Speed:1000m—1200m /Hour; Width:1.6m

Clean 14 tons to 16 tons a day on average each line

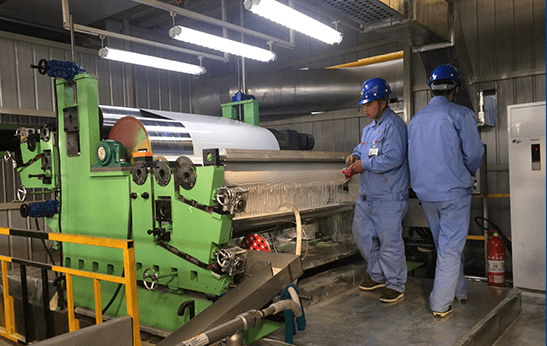

ALUSONG has two aluminum coating lines with high speed. The coating line is to coat the chemosythesized aluminum roll with various paints according to the needs of the customers. We have an advanced three-roller reversal precision coating machine that can operate under sealed, dustless condition so that the thickness of coating and its outer appearance are under proper control. The oven is divided into four temperature-controlled areas to make the coating reach the best condition in its solvent resistance, hardness, feasibility and good glossiness, strong adhesive force and corrosion resistance. Speed:Average 1000m /Hour; Max Width:1.6m

Coating capacity: 15000~17000㎡ a day on average for each line.

ALUSONG has 7 high speed lamination production lines. These are the key equipment of producing aluminum composite panels. It can make aluminum material. LDPE core board and adhesive poly film firmly adhesive to one another under high heat and high pressure so that the panel is smooth in surface.With imported qualified adhesive poly film,advanced equipment, perfect technology and strict quality control, we have produced the aluminum plastic composite panel whose peel strength is superior compared with the quality index of imported panels. Speed:2.8m/ Min Max Width: 1.6m

Composite Capacity: 4800m2/ daily each day

Premium Services

Free samples, free color chart and installation diagram and other promotional materials, people-oriented, premium services.

Technical support of international well-known partner, provides professional technical guidance.

Authorized a qualified distributors friendship.

ALUSONG owns complete the total solution system and 7 production lines to ensure timely delivery.

Abide by the credibility and do the best for customers. 24 hours online service